Para-Fashion: Automatic bespoke parametric Fashion made practical

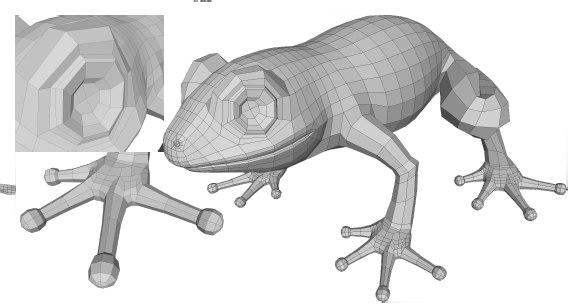

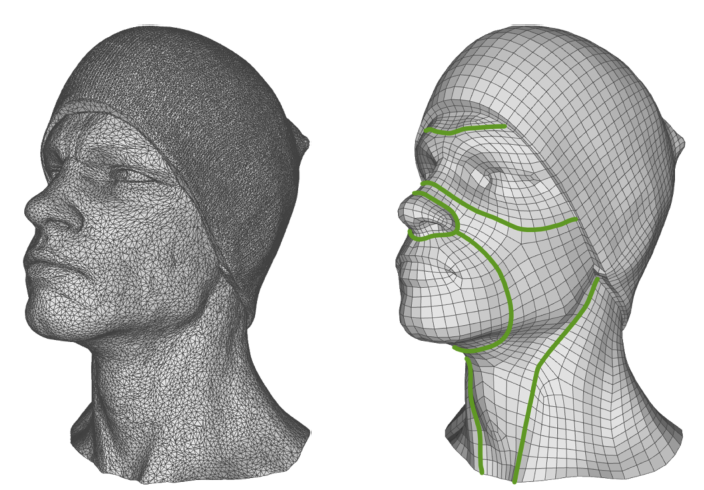

The recent rise in demand for individualized garment and the increased capacity of manufacturing offered by modern digital fabrication devices had traced the path for a novel set of semi-automatic design tools that assist the fashion designer in the effective creation and production of dresses. Despite the advent of this digital modelling pipelines, the majority of processes in the fashion industry are still inefficient and heavily dependent on manual work. Considering the size of the fashion industry, automatizing some of the main methods, might produce a beneficial impact on the overall process. Concurrently we assisted to a significant rise in industrial applications of 3D acquisition, processing and optimization of 3D data. Recent technologies allow producing a clean representation of a real-world object or even acquire the shape of the human body. Contemporarily the development of novel shape analysis and geometry processing techniques had created a new arsenal of technologies that are capable of anticipating the physical behaviour and then optimize the design and fabrication of real cloths. However, nobody had successfully integrated all these aspects to a fully digital optimization process to create bespoke optimized dresses.

Challenges

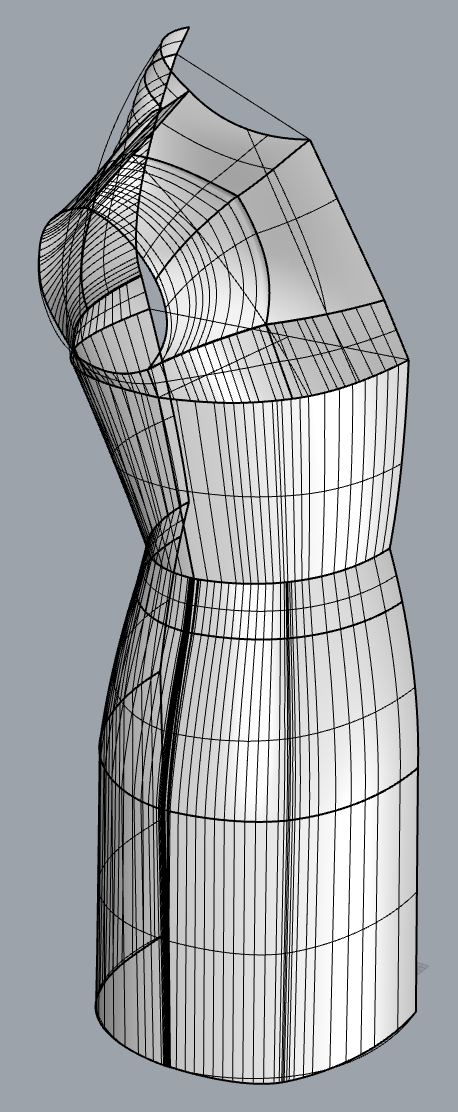

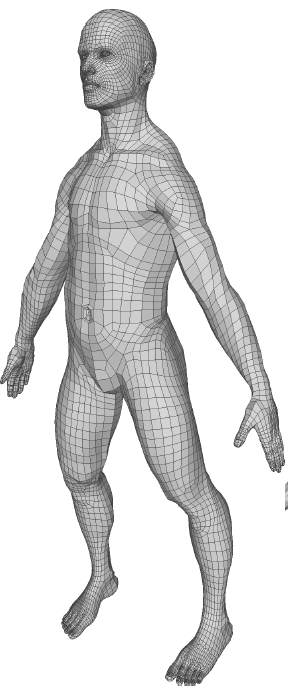

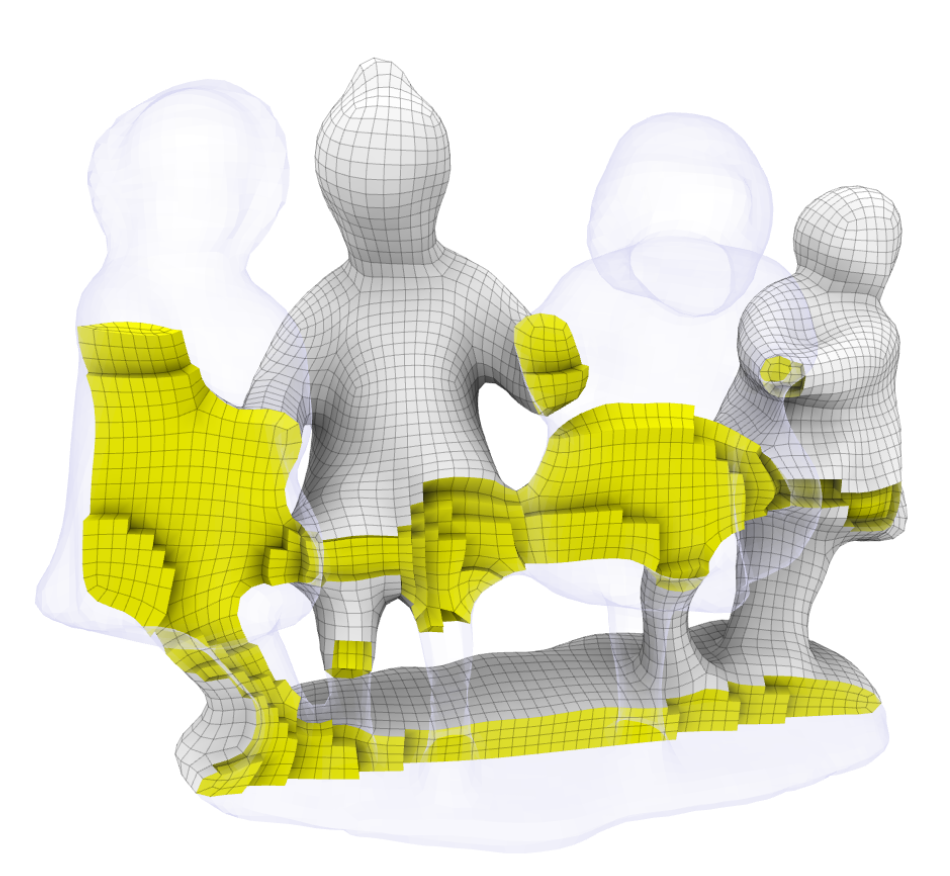

In this project, we aim at creating a pipeline that fits digital clothes into a personalized 3D scanned model of the human body and as automatically derives the optimal sewing patterns. Specifically:

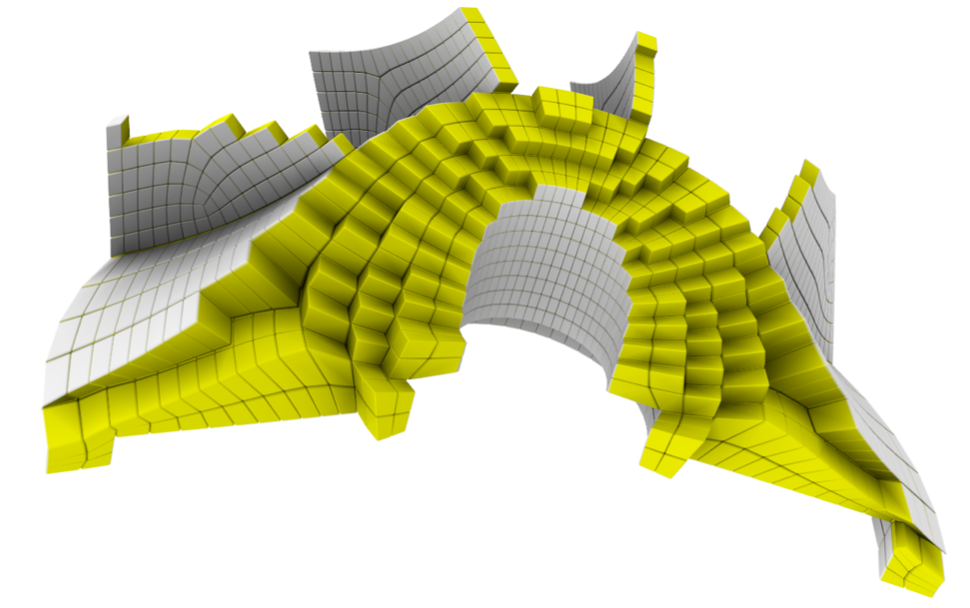

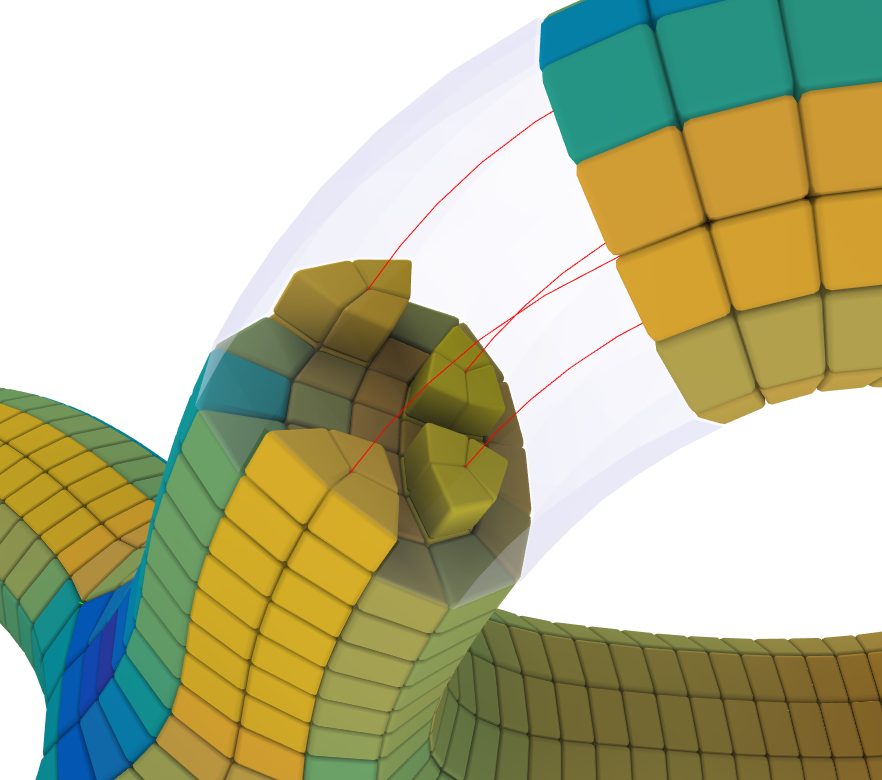

- Define a procedure which is capable of fitting the digital model of cloth into an acquired point cloud which approximate and individual's human body.

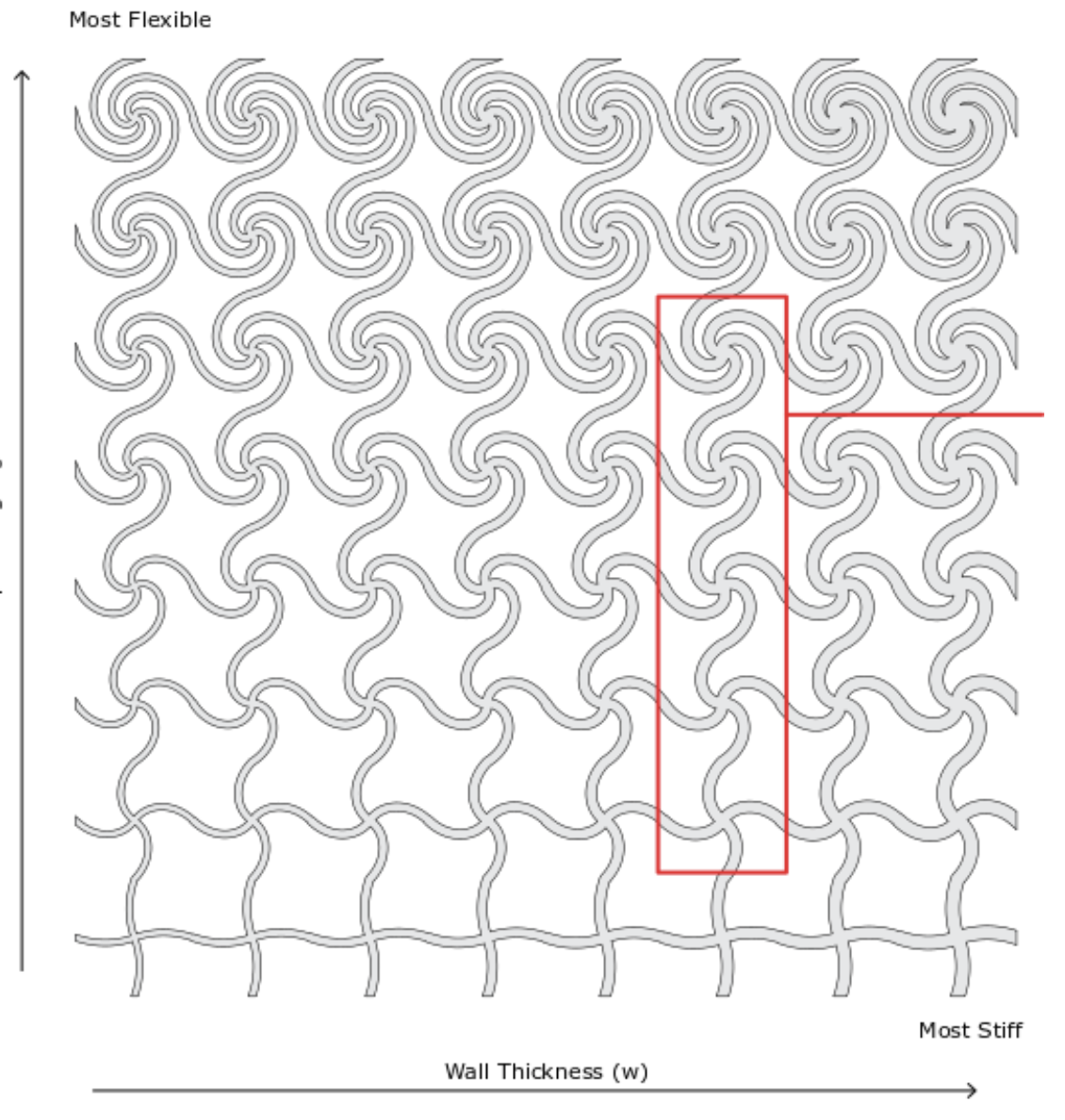

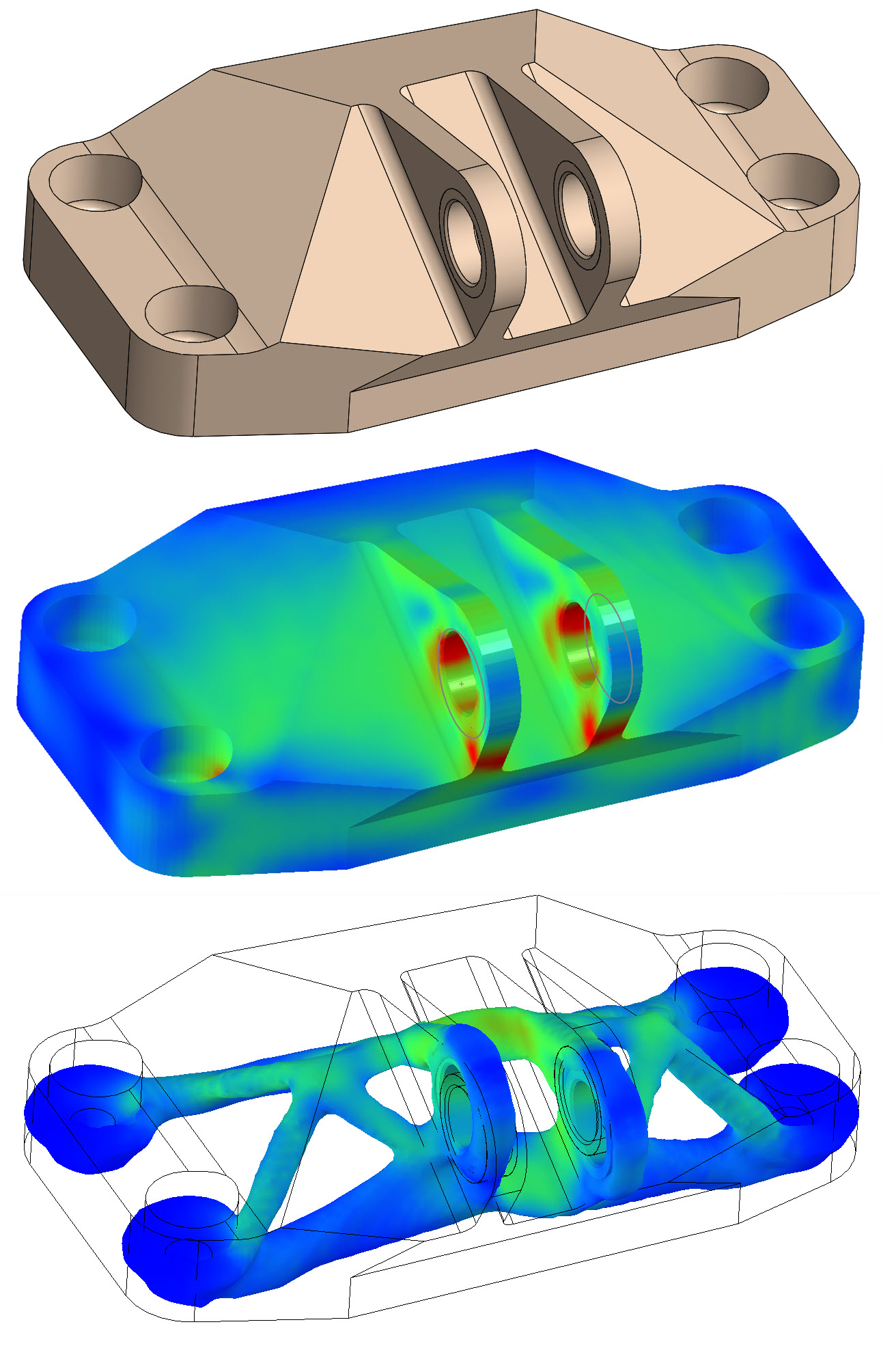

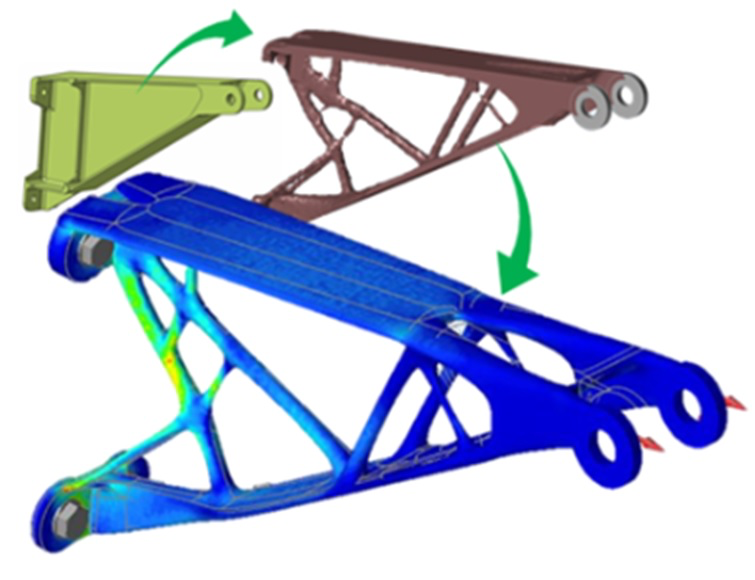

- Optimize the sewing pattern and assist the designer in the modification of the current patch decomposition of the cloth. This step should illustrate on the fly where the tissue experiences the major deformations/tensions/compression and suggest the artist new cuts to accommodate for such geometric setup.

- Exploit deeply trained model to build a novel software pipeline that automatically creates sewing patterns for new digital creation.