Digital Fabrication

Since the early 2010s, the Visual Computing Lab has been very active in the digital fabrication domain. The research pursued in this field investigates novel methods and algorithms for two primary goals. We research solutions to enhance the capabilities of existing digital fabrication devices, such as 3D printers and CNCs. Additionally, the research is focused on developing new fabrication processes or improving the existing ones, exploiting the potential of computational design and digital manufacturing devices.

The research activity is conducted by combining expertise in different fields related to Computer Graphics, namely geometry processing, geometric modeling, physical simulation, numerical optimization and shape analysis. The results of this research have been published in several papers in top-tier conferences and journals in the field of Computer Graphics and Computer-Aided Design (ACM Transactions on Graphics, SIGGRAPH, SIGGRAPH Asia, Eurographics, etc.).

The produced methods and algorithms provide automated methods for several applications like manufacturing a stylized representation of a 3D model, designing flexible molds for casting, optimizing the model decomposition for 3D printing, synthesizing 3D-printable metamaterials, and architectural design. Relevant expertise in digital fabrication has been exploited in the context of several research projects, including Italian Government PRIN DSurf, EU Horizon 2020 ITN Evocation, and EU Horizon 2020 EMOTIVE.

Below is a selection of representative research works in the field.

- Field-aligned mesh joinery

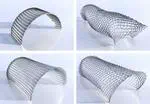

- Elastic textures for additive fabrication

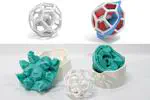

- FlexMolds: automatic design of flexible shells for molding

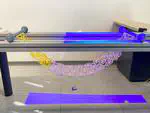

- FlexMaps: Computational Design of Flat Flexible Shells for Shaping 3D Objects

- Volume-aware design of flexible molds

- Optimizing Object Decomposition to Reduce Visual Artifacts in 3D Printing